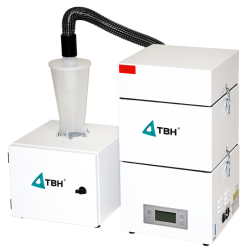

TBH FP 150 ATEX Automatic Cleaning z filtrem cząstek i węglem aktywnym

Odciąg zanieczyszczeń FP 150 ATEX Automatic Cleaning z filtrem cząstek i węglem aktywnym

Wyjątkową zaletą modeli FP odróżniającą je od całej reszty systemów odciągowych jest zastąpienie saturatorów specjalnymi kartridżami. Jest to nic innego jak specjalne filtry samoczyszczące. Każdy system odciągu stworzony został by odpowiedzieć na różne potrzeby wynikające z zapotrzebowania na ochronę użytkowników. Kartridże świetnie sprawdzają się przy pracy z zanieczyszczeniami widocznymi gołym okiem, które mają postać fizycznych okruchów. Nie każda praca wymaga saturatorów, które są niezastąpione przy gazach, zapachach, czy bardzo drobnych cząsteczkach. Dzięki temu przeznaczeniu kartridże w serii FP można wielokrotnie czyścić przed ich zużyciem.

Kartridże

- dla pyłów klasy M

- Poliestrowa powłoca antystatyczna z mikrofibry

- Specjalna powłoka pokrywająca zabezpieczająca przed uszkodzeniami mechanicznymi

- Czyszczenie sprężonym powietrzem

Zastosowanie

Obróbka laserowa (również z połączeniu z wstępnym zabezpieczeniem filtra)

Obróbka mechaniczna (szlifowanie, usuwanie zadziorów, frezowanie, wiercenie, cięcie)

Przenoszenie, pakowanie, transport materiałów

Wielofunkcyjny odciąg pyłów

Liczne zalety systemu

Konstrukcja modułowa – możliwość dodania różnych modułów filtrów

Możliwość czyszczenia wkładu filtra

Szybkie usuwanie nagromadzonych pyłów

Wielofunkcyjna elektronika sterująca

Zanieczyszczone powietrze gromadzone jest przez system odciągu powietrza (wyciąg, przewód ssawny, rura, itp.) i przekazywane do filtra bezpośrednio lub poprzez giętki wężyk lub rurkę.

Cząstki pyłu filtrowane są przez wkład filtra, który można następnie czyścić ręcznie przy pomocy pistoletu ze sprężonym powietrzem, jednak ze względów zdrowotnych zaleca się stosowanie opcjonalnego automatycznego systemu czyszczenia.

W momencie, gdy skuteczność odciągu maleje, czujniki różnicy ciśnień uruchamiają system automatyczny. Odfiltrowane cząstki pyłu gromadzą się w pojemniku, który można łatwo opróżnić. W celu uniknięcia rozsypania pyłu, można również umieścić go w worku.

Możliwość dodania różnych modułów filtrów

ATEX Automatic Cleaning z filtrem cząstek i węglem aktywnym

Można zamontować opcjonalny filtr przeciwpyłowy (H13) w celu zwiększenia skuteczności separacji zanieczyszczeń, np. w przypadku odciągu substancji rakotwórczych. Kolejną opcją jest zastosowanie filtrów wyposażonych w sito molekularne (np. filtrów z węglem aktywnym/granulatem BAC), które eliminują nieprzyjemne zapachy. Do każdego dodatkowego modułu filtra należy zamówić podest, aby zapewnić stabilność systemu.

Szybkie usuwanie nagromadzonych pyłów

Pyły zgromadzone w filtrze można usunąć poprzez wyjęcie przenośnego pojemnika. W celu uniknięcia rozsypania pyłu, pojemnik można również umieścić w worku.

Każdy system FP wyposażony jest w elektroniczne systemy sterowania INSPIRE oraz wszechstronny interfejs, które zapewniają sterowanie i monitorowanie następujących funkcji:

- Przełączanie pomiędzy trybem pracy/czuwania

- Ręczna regulacja prędkości obrotów

- Ręczne uruchomienie systemu czyszczenia filtra

- Wskaźnik nasycenia filtra w systemie odciągu

- Wizualna i dźwiękowa sygnalizacja zapełnienia filtra

- Sygnalizacja awarii (wyświetlenie i powiadomienie)

Interfejs

- Start/stop systemu

- Ostrzeżenie o nasyceniu filtra w 75% (komunikat – np. zewnętrzna kontrola procesu czyszczenia filtra)

- Wizualna i dźwiękowa sygnalizacja zapełnienia filtra

- Zbiorcze komunikaty awarii (prędkość obrotów, temperatura, zapełnienie

- filtra w 100%)

- Zewnętrzna regulacja prędkości obrotów

- Załączenie systemu czyszczenia filtra

- Rejestracja błędów zapewnia sprawną koordynację pomiędzy klientem a serwisem TBH

- Ustawienie parametrów w celu dostosowania funkcji do potrzeb klienta

Elementy robocze systemu

- Przełącznik pomiędzy trybem pracy/czuwania

- Ręczna regulacja prędkości obrotów

- Ręczny włącznik systemu czyszczenia filtra

- Wskaźnik nasycenia filtra

- Sygnalizacja stanu systemu

- Wskaźnik ustawień systemu

- Licznik czasu pracy

- Wskaźnik temperatury i sygnalizator awarii turbiny

- Wskaźnik stanu filtra

Bezpieczeństwo przemysłowe i ochrona zdrowia

Aby w jeszcze większym stopniu spełniać wymogi naszych klientów w zakresie bezpieczeństwa, TBH uzupełnia swoją ofertę produktów, wprowadzając różne systemy odciągu i filtracji zanieczyszczeń poddane specjalnym testom w niemieckim Instytucie Bezpieczeństwa Pracy (Institut für Arbeitsschutz (IFA)) zgodnie z wymogami normy DIN ISO 15012-1 (2013).