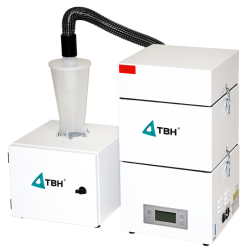

TBH BF 1200R

Filtr zanieczyszczeń i odciąg oparów BF1200R

Produkty należące do serii BF (FILTRACJA PODSTAWOWA) zostały zaprojektowane jako modele podstawowe, które oferują wszystkie istotne funkcje systemu odciągu i filtracji, a jednocześnie korzystny stosunek osiągów produktu do jego ceny.

Poszczególne urządzenia z serii BF posiadają różne napędy, filtry oraz parametry robocze. Cała seria produktów oparta została na modułowej konstrukcji TBH, wykorzystując wszystkie jej zalety.

Dobranie odpowiedniego modelu z serii BF powinno odbywać się w oparciu o czas pracy (jak długo ma być urządzenie włączone) oraz na ilości wydobywających się zanieczyszczeń.

Zastosowanie

- Lutowanie (odciąg pojedynczy/równoległy)

- Obróbka laserowa (odciąg zanieczyszczeń, kompaktowe lasery)

- Procesy generujące pyły kleiste/wilgotne

- Procesy generujące opary/gazy

Zalety systemu

- Modułowa konstrukcja

- Szybka wymiana wkładu filtracyjnego

- Wskaźnik różnicy ciśnień monitorujący filtry saturacyjne

- Produkty serii BF wyposażone w dmuchawy oferują wyjątkową energooszczędność

- Podstawowe funkcje elektroniki sterującej

Modułowa konstrukcja

Łatwość obsługi i konserwacji urządzenia to ogromny PLUS konstrukcji modułowej, ponieważ w razie potrzeby czynnościom diagnostycznym poddaje się wyłącznie wadliwy moduł, a nie cały system. Na czas naprawy można również podłączyć moduł zastępczy. Obniża to koszty ewentualnych przestojów w procesie produkcji.

Szybka wymiana filtra

W celu wymiany filtra należy go po prostu usunąć z górnej części urządzenia. Zapewnia to szybką i czystą wymianę filtra przez pracowników lub personel przeprowadzający czynności konserwacyjne.

Energooszczędność

Zastosowanie specjalnych dmuchaw w modelach BF5 i BF10 umożliwia wyjątkowo energooszczędne konfiguracje systemu (< 0,2 kW).

Seria BF wyposażona w turbinę

Te urządzenia z serii BF wytwarzają szczególnie wysokie podciśnienie, idealnie więc nadają się do odciągania zanieczyszczeń przy pomocy niewielkich systemów odciągu czy nawet urządzeń należących do klienta, lub też przy pomocy długich kanałów odciągowych. Umożliwiają również zdecentralizowaną instalację systemu odciągu w wielu miejscach (tj. na wielu stanowiskach roboczych). Jeżeli szukacie Państwo skutecznego systemu do specjalnych zastosowań, prosimy o kontakt z zespołem TBH ds. sprzedaży.

Seria BF wyposażona w dmuchawę (wentylator)

Te urządzenia z serii BF posiadają kompaktową konstrukcję i są szczególnie energooszczędne. Przeznaczone są do montażu nastołowego na pojedynczych lub podwójnych stanowiskach roboczych wyposażonych w przewód ssawny, np. do odciągu oparów powstających w trakcie lutowania. Ich konstrukcja wymaga każdorazowego sprawdzenia, czy średnica na wlocie jest odpowiednio duża (w przeciwieństwie do modeli z serii LN).

Urządzenia należące do serii BF wyposażone są w elektroniczne systemy sterowania INSPIRE w konfiguracji podstawowej:

- Przełączanie pomiędzy trybem pracy/czuwania

- Ręczna regulacja prędkości obrotów

- Wskaźnik nasycenia filtra w systemie odciągu

- Wizualna i dźwiękowa sygnalizacja zapełnienia filtra

- Sygnalizacja awarii

Interfejs

- Start/stop systemu

- Ostrzeżenie o nasyceniu filtra w 75%

- Wstępne ustawienie trybu pracy/czuwania przy uruchomieniu systemu

Wymiary

- Waga: 90kg

- Wysokość: 110,5cm

- Szerokość: 35cm

- Głębokość: 65,5cm

Konfiguracja filtra

- Z-linepanel Plus Filtr F7

- Filtr cząstek H13

- węgiel aktywny/ filtr BAC

Elementy robocze systemu

- Przełącznik pomiędzy trybem pracy/czuwania

- Ręczna regulacja prędkości obrotów

- Wskaźnik nasycenia filtra

- Sygnalizacja stanu systemu

- Wskaźnik ustawień systemu

- Licznik czasu pracy

- Wskaźnik temperatury i sygnalizator awarii turbiny (z wyjątkiem modelu BF 9)

- Wskaźnik stanu filtra

Aby w jeszcze większym stopniu spełniać wymogi naszych klientów w zakresie bezpieczeństwa, TBH uzupełnia swoją ofertę produktów, wprowadzając różne systemy odciągu i filtracji zanieczyszczeń poddane specjalnym testom w niemieckim Instytucie Bezpieczeństwa Pracy (Institut für Arbeitsschutz (IFA)) zgodnie z wymogami normy DIN ISO 15012-1 (2013).