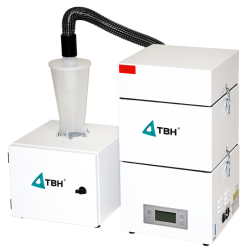

TBH LN 260

Odciąg zanieczyszczeń LN 260

Kompaktowa i modularna budowa zapewnia, zależnie od procesu, prostą adaptację urządzenia. System z turbinami wysokiej wydajności może być zdecentralizowany i przeprowadzać proces ekstrakcji z długiego dystansu.

Model o większej wydajności niż LN230.

Liczne zalety systemu

Konstrukcja modułowa – możliwość dodania różnych modułów filtrów

Szybka wymiana wkładu filtracyjnego

Duże podciśnienie zapewniające bardzo skuteczny odciąg

Wielofunkcyjna elektronika sterująca

Zanieczyszczone powietrze gromadzone jest przez system odciągu powietrza (wyciąg, przewód ssawny, rura, itp.) i przekazywane do filtra bezpośrednio lub poprzez giętki wężyk lub rurkę. W filtrze zanieczyszczone cząstki przechodzą przez różne poziomy filtracji, w zależności od ich rozmiarów.

Filtry wyposażone w sito molekularne (np. filtry z węglem aktywnym/granulatem BAC) usuwają większość zanieczyszczeń gazowych. Oczyszczone powietrze jest następnie zawracane do stanowiska pracy lub odprowadzane na zewnątrz przewodem wylotowym. Recyrkulacja powietrza na stanowisku pracy pozwala w łatwy sposób obniżyć koszty zużycia energii.

Możliwość dodania różnych modułów filtrów

W zależności od zastosowania, systemy filtracji z serii LN 200 można złożyć z różnych modułów filtrów. Optymalizuje to koszty i umożliwia odpowiednie dostosowanie system odciągu i filtracji do zmieniających się warunków roboczych i wymogów klienta.

Szybka wymiana filtra

W celu wymiany filtra należy go po prostu wyjąć z górnej części urządzenia. Zapewnia to szybką i czystą wymianę filtra przez pracowników lub personel przeprowadzający czynności konserwacyjne.

Duże podciśnienie = duża siła odciągu

Urządzenia z serii LN 200 wytwarzają szczególnie wysokie podciśnienie, idealnie więc nadają się do odciągania zanieczyszczeń przy pomocy niewielkich systemów odciągu czy nawet urządzeń należących do klienta, lub też przy pomocy długich kanałów odciągowych. Umożliwiają również zdecentralizowaną instalację systemu odciągu w wielu miejscach (tj. na wielu stanowiskach roboczych). Jeżeli szukacie Państwo skutecznego systemu do specjalnych zastosowań, prosimy o kontakt z zespołem TBH Polska.

Wymiary

- Waga: 60kg

- Wysokość: 75cm

- Szerokość: 35cm

- Głębokość: 65,5cm

Konfiguracja filtra

- pre-filtr mat M5

- filtr cząstek H13

- węgiel aktywny/BAC filtr

Interfejs

- Start/stop systemu

- Ostrzeżenie o nasyceniu filtra w 75%

- Wizualna i dźwiękowa sygnalizacja zapełnienia filtra

- Zbiorcze komunikaty awarii (prędkość obrotów, temperatura, zapełnienie

- filtra w 100%)

- Zewnętrzna regulacja prędkości obrotów

- Rejestracja błędów zapewnia sprawną koordynację pomiędzy klientem a serwisem TBH

- Ustawienie parametrów w celu dostosowania funkcji do potrzeb klienta

Elementy robocze systemu

- Przełącznik pomiędzy trybem pracy/czuwania

- Ręczna regulacja prędkości obrotów

- Wskaźnik nasycenia filtra

- Sygnalizacja stanu systemu

- Wskaźnik ustawień systemu

- Licznik czasu pracy

- Wskaźnik temperatury i sygnalizator awarii turbiny

- Wskaźnik stanu filtra

Bezpieczeństwo przemysłowe i ochrona zdrowia

Aby w jeszcze większym stopniu spełniać wymogi naszych klientów w zakresie bezpieczeństwa, TBH uzupełnia swoją ofertę produktów, wprowadzając różne systemy odciągu i filtracji zanieczyszczeń poddane specjalnym testom w niemieckim Instytucie Bezpieczeństwa Pracy (Institut für Arbeitsschutz (IFA)) zgodnie z wymogami normy DIN ISO 15012-1 (2013).

Adsorbcia zanieczyszczeń gazowych

Dwa komplementarne wkłady filtrujące zapewniają adsorpcję substancji gazowych. Aktywny węgiel ułatwia fizyczną adsorpcję, a biologicznie aktywny granulat BAC umożliwia proces adsorpcji chemicznej. Neutralizacja konkretnych zanieczyszczeń gazowych odbywa się poprzez chemiczne wiązanie z substancją reagującą osadzoną na materiale nośnym. Procesy adsorpcji fizycznej i chemicznej są komplementarne, umożliwiają więc usunięcie bardzo szerokiego zakresu gazów i nieprzyjemnych zapachów.